Stations

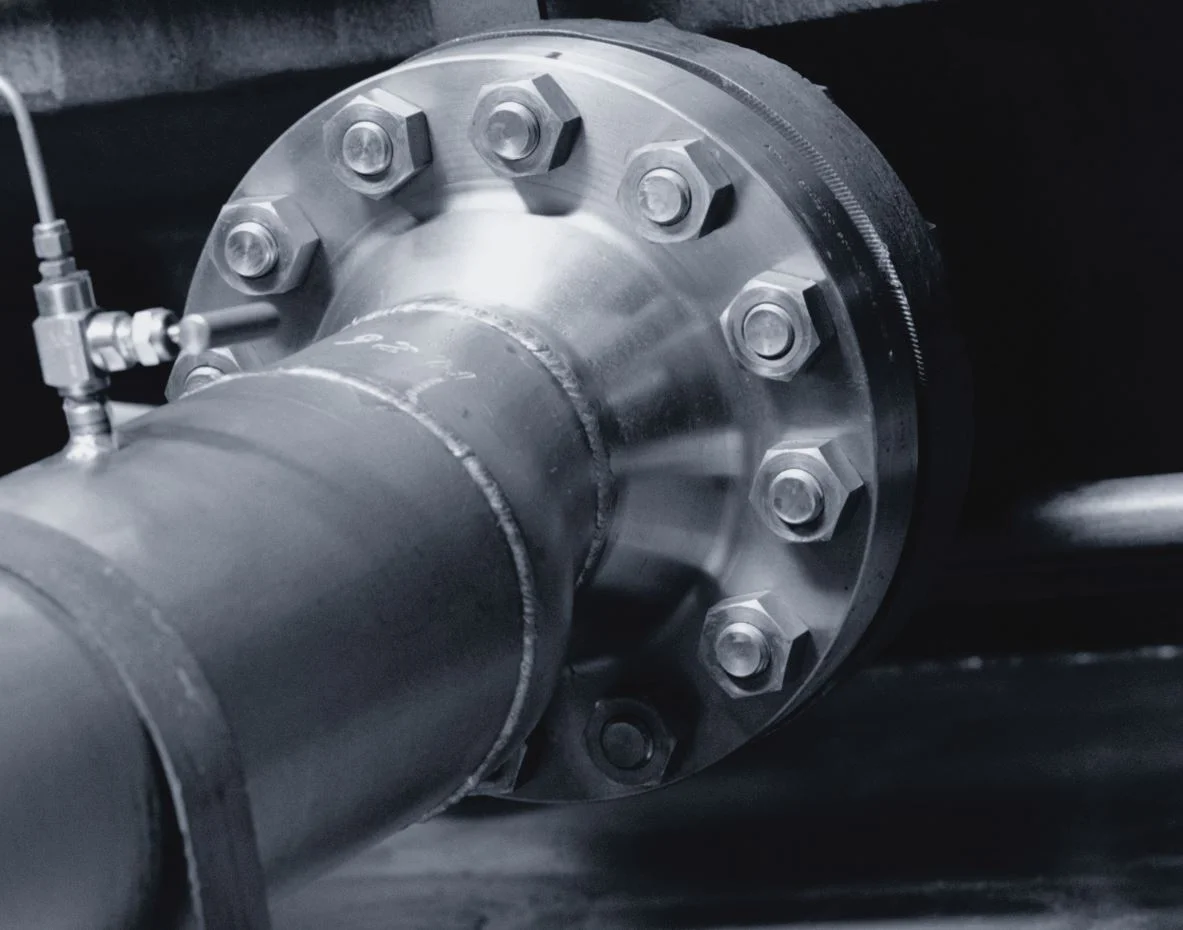

Meter and Regulator Stations

LARGE POWER PLANT

The scope of this project required the complete redesign of an existing meter and regulating station, within a 6-month time frame, and had to provide an increased capacity to feed an 11.5 MW power generating plant. The power generating plant required a maximum capacity of 13,000 mscfh, with an operating pressure at 120 psig.

The M&R station was designed with two 8,000 Mbtuh indirect fired heaters, a 13,000 mscfh filter separator, and four separate metering runs running in pairs. Two low flow runs utilized Roots rotary meters and Mercury correctors while two high capacity runs were outfitted with Q-sonic, 5-path ultrasonic meters. The M&R station also had four regulator runs, two runs for each primary boiler, creating a pressure cut from 750 psig inlet to 120 psig outlet.

The required scale of this project resulted in the use of larger equipment such as, 12-inch Dual-port Regulators, 24-inch Ball valves with Bettis Actuators, and a 30-inch ball valve for a header transitioning between the meter and regulator runs.

The overall footprint was larger than usual and presented some challenges with site development. Part of the design included an access road around the perimeter of the M&R station. Other site requirements included fencing, grading, grounding, walkways, and platforms.

LEGACY STATION REPLACEMENT, RI

An existing station consisted of six above ground interconnected district regular stations, cutting the pressure from a 200 psig feed down to as low as 7 psig. The scope of the project was to rebuild the entire existing station with a new pre-fab concrete enclosure for multiple regulator runs at a flow capacity of 6,627 mscfh and pressure cut from 200 psig to 99 psig in a multi-phase and multi-year design.

The design included three regulator runs, a primary and secondary run with a backup run. Each run consists of an inlet isolation valve, strainer, over pressurization protection regulator, monitor regulator, control regulator, and isolation valve. The inlet and outlet of these three runs were designed with a common header. As an additional requirement of the design, the entire facility needed to be elevated 7-feet above existing grade to account for possible flooding during major storms from local waterways.

Part of the design also included the design of a filter separator on the station inlet and below grade regulator vaults for distribution at additional pressure cuts from the required 99 psig station outlet to 35 psig, 10 psig, and 7 psig at multiple locations for system feeds throughout the city it serves.

LEGACY STATION REPLACEMENT, ME

PPS was hired to design a new regulator station to replace an older one. Our client was in a position where the location of an existing regulator station was no longer available for their use. The new location would require a much smaller footprint, while maintaining the same (or increased) capacity to a large city. Challenges included land use agreements, permitting, documentation research, surveying, and existing utility locations. The work and design was to be performed in conjunction with other neighboring design projects. The biggest challenge was maintaining service while transitioning from the old station to the new station. By phasing portions of the project, PPS was able to assist our client in providing a seamless transition that never disrupted the city’s natural supply.

The final design of the new regulator station provided service to 4 separate main lines with outlet pressures of ranging from low pressure to 56 psig. A 12-inch Peerless filter fed into a 12-inch meter run with a Elster American flow meter. 3 separate regulator runs with additional bypass runs.

RETROFIT, MA

The scope of this project was to retrofit an existing brick structure with four new regulator runs, consisting of two high pressure runs and two low pressure runs. The inlet pressure for the station is 200 psig reduced to outlet pressures of 60 psig and 12 inches water column low pressure. The existing roof structure, windows and doors needed to be updated. The site also required regrading and installation of drainage to accommodate the issue of pooling stormwater on site.

Contact us for more information

info@processpipeline.com

4 Broad Street

Plainville, MA 02762

781.829.0524

or

40 South River Road, Unit 12

Bedford, NH 03110

603.935.8201